RBS-C wurde für den Materialumschlag zwischen zwei Förderbändern in Ihrem Werk entwickelt.

Da die Lade- und Abwurfprozesse vollautomatisch sind, wird der Automatisierungsgrad auf den höchsten Stand gebracht.

Überlassen Sie die Kommunikation zwischen Förderbändern und FTF der ROBOS Control © -Software.

|

Specifications |

1.1 |

Manufacturer |

|

ROBOS |

ROBOS |

|

1.2 |

Manufacturer’s type designation |

RBS-C05 |

RBS-C1 |

||

|

1.3 |

Drive type |

Differential |

Differential |

||

|

1.4 |

Handling type |

Conveyor |

Conveyor |

||

|

1.5 |

Load capacity / rated load |

kg |

500 |

1.000 |

|

|

1.6 |

Service weight (Incl. batteries) |

kg |

560 |

650 |

|

|

Tires |

2.1 |

Tire type |

|

Poliurethane |

Poliurethane |

|

2.2 |

Tire diameter front/rear |

150/250 |

150/250 |

||

|

2.3 |

Wheels number front/rear |

2/2x |

2/2x |

||

|

Dimensions |

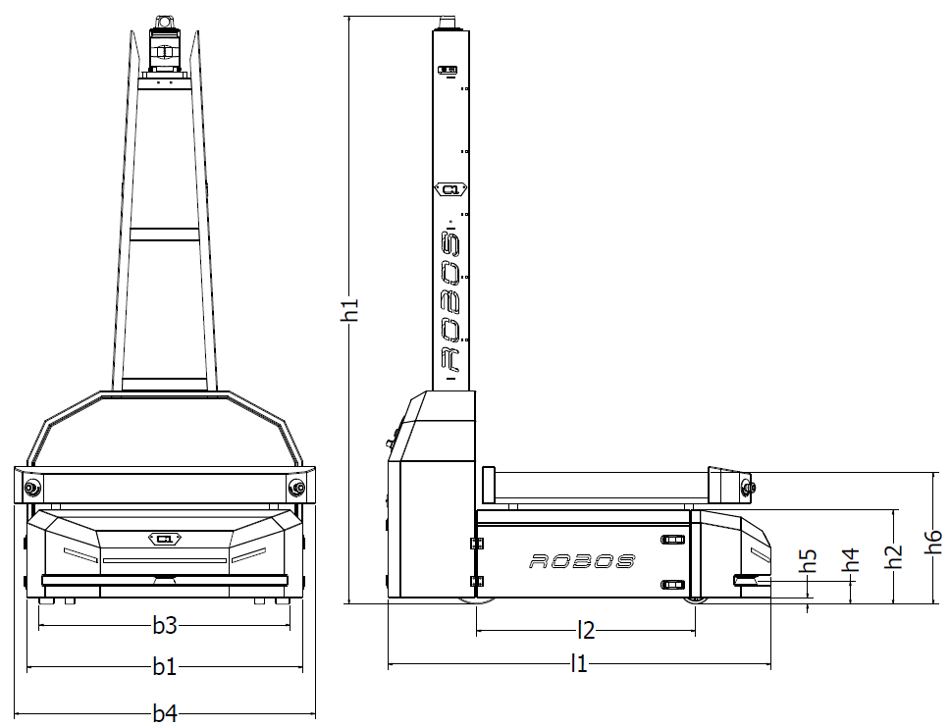

3.1 |

Overall height |

h1 |

2.260 |

2.260 |

|

3.2 |

AGV base height |

h2 |

325 |

350 |

|

|

3.3 |

Coupling height |

h3 |

– |

– |

|

|

3.4 |

Safety scan height |

h4 |

90 |

105 |

|

|

3.5 |

Ground clearence |

h5 |

25 |

25 |

|

|

3.6 |

Loading base height |

h6 |

400 (+200) |

500 (+200) |

|

|

3.7 |

Overall lenght |

l1 |

1.400 |

1.500 |

|

|

3.8 |

Wheelbase |

l2 |

850 |

850 |

|

|

3.9 |

Overall width |

b1 |

750 |

1.100 |

|

|

3.10 |

Tread, rear |

b3 |

650 |

1.000 |

|

|

3.11 |

Min. Loading area width |

b4 |

750 |

1.100 |

|

|

Performance |

4.1 |

Max. travel speed |

mpm |

62 |

62 |

|

4.2 |

Gradeability (With full load) |

1% |

1% |

||

|

4.3 |

Drive motor number |

2 |

2 |

||

|

4.4 |

Total drive motor power |

kW |

0,80 |

1,50 |

|

|

4.5 |

Rated drawbar pull |

N |

– |

4.100 |

|

|

Battery |

5.1 |

Battery type |

|

Gel |

Gel |

|

5.2 |

Battery voltage |

V |

48 |

48 |

|

|

5.3 |

Battery capacity K20 |

Ah |

110 |

130 |

|

|

5.4 |

Battery weight |

kg |

140 |

195 |

|

|

5.5 |

Expected worktime per charge |

hr |

9,23 |

8,41 |