RBS-C was created for material handling between two conveyors in your factory.

As the loading and dropping processes are fully automatic, it brings the automation level to the highest level.

Leave communications between conveyors and AGVs to ROBOS Control © software.

|

Specifications |

1.1 |

Manufacturer |

|

ROBOS |

ROBOS |

|

1.2 |

Manufacturer’s type designation |

RBS-C05 |

RBS-C1 |

||

|

1.3 |

Drive type |

Differential |

Differential |

||

|

1.4 |

Handling type |

Conveyor |

Conveyor |

||

|

1.5 |

Load capacity / rated load |

kg |

500 |

1.000 |

|

|

1.6 |

Service weight (Incl. batteries) |

kg |

560 |

650 |

|

|

Tires |

2.1 |

Tire type |

|

Poliurethane |

Poliurethane |

|

2.2 |

Tire diameter front/rear |

150/250 |

150/250 |

||

|

2.3 |

Wheels number front/rear |

2/2x |

2/2x |

||

|

Dimensions |

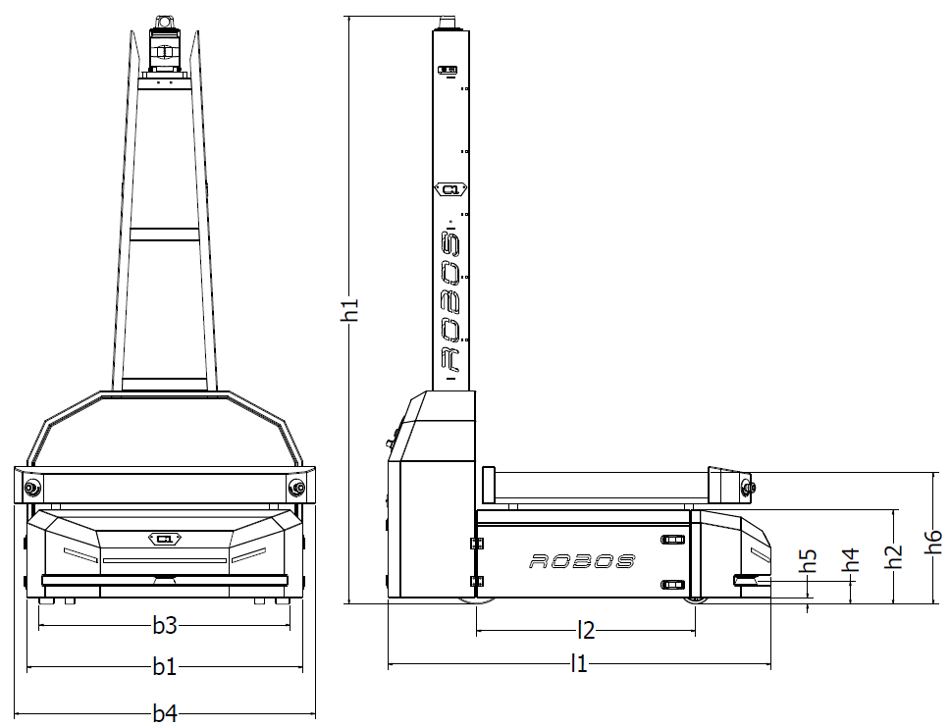

3.1 |

Overall height |

h1 |

2.260 |

2.260 |

|

3.2 |

AGV base height |

h2 |

325 |

350 |

|

|

3.3 |

Coupling height |

h3 |

– |

– |

|

|

3.4 |

Safety scan height |

h4 |

90 |

105 |

|

|

3.5 |

Ground clearence |

h5 |

25 |

25 |

|

|

3.6 |

Loading base height |

h6 |

400 (+200) |

500 (+200) |

|

|

3.7 |

Overall lenght |

l1 |

1.400 |

1.500 |

|

|

3.8 |

Wheelbase |

l2 |

850 |

850 |

|

|

3.9 |

Overall width |

b1 |

750 |

1.100 |

|

|

3.10 |

Tread, rear |

b3 |

650 |

1.000 |

|

|

3.11 |

Min. Loading area width |

b4 |

750 |

1.100 |

|

|

Performance |

4.1 |

Max. travel speed |

mpm |

62 |

62 |

|

4.2 |

Gradeability (With full load) |

1% |

1% |

||

|

4.3 |

Drive motor number |

2 |

2 |

||

|

4.4 |

Total drive motor power |

kW |

0,80 |

1,50 |

|

|

4.5 |

Rated drawbar pull |

N |

– |

4.100 |

|

|

Battery |

5.1 |

Battery type |

|

Gel |

Gel |

|

5.2 |

Battery voltage |

V |

48 |

48 |

|

|

5.3 |

Battery capacity K20 |

Ah |

110 |

130 |

|

|

5.4 |

Battery weight |

kg |

140 |

195 |

|

|

5.5 |

Expected worktime per charge |

hr |

9,23 |

8,41 |